At Manufacturas Metalúrgicas RSL it is essential in our philosophy to have great professionals in all areas, giving the same importance to each and every one of them.

Much attention is usually paid to what we call "offices" as the matrix of business success, nothing is further from reality, since each and every one of the positions in a business structure have the same importance and are fundamental in achieving of objectives for this are in continuous communication throughout the production process.

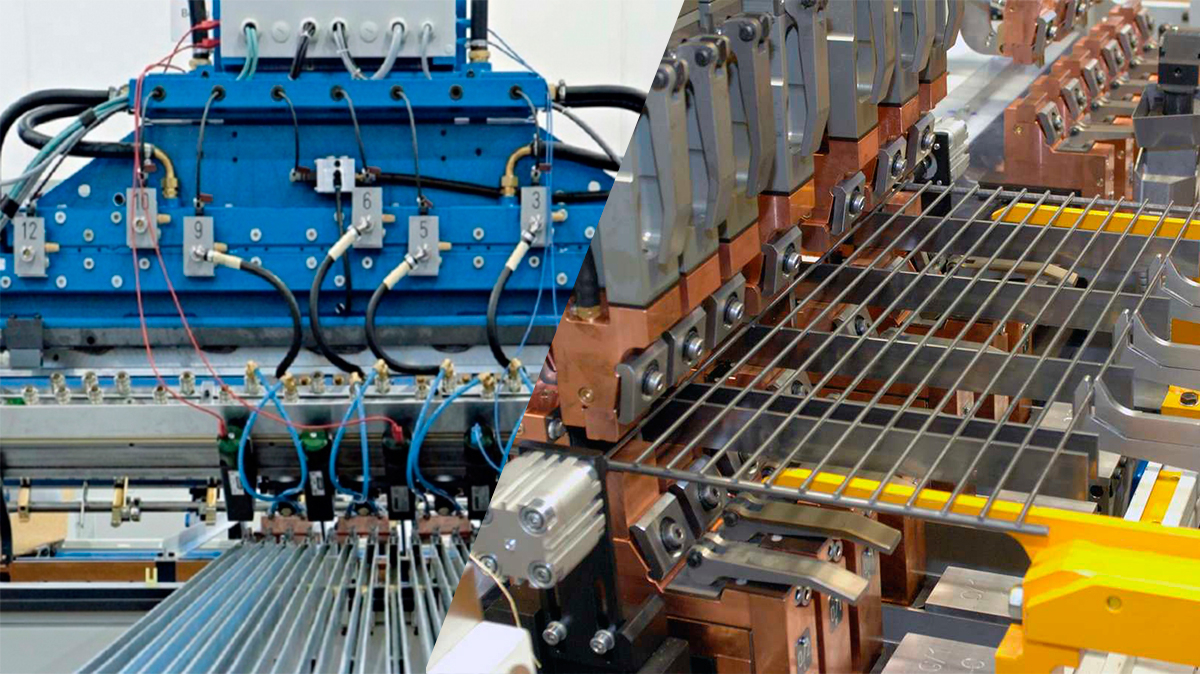

In our company we have a great production and manufacturing team, all of them in continuous training in the use and handling of the latest applied technology machinery.

Our production team vital in development.

Not only at the time of developing a project are the opinions of the sales team and designers taken into account, but it is essential, to meet deadlines and achieve an impeccable final product following the client's guidelines, to have the advice of our manufacturing managers. .

It is at this moment when, once all the points of the project have been agreed upon, the manager or the production manager will indicate the objective that has to be achieved to the rest of the team, something that must be taken into account when collecting the information. raw material, in perfect communication with the Purchasing Department.

Just great quality.

Without a doubt, our hallmark is the perfection of the final product thanks to perfect processes and exhaustive quality control.

At this stage it is essential to follow the production strategy and carry out work observing the environment, in such a way that changes can be anticipated and an action plan can be drawn up to know how to act at all times to continue working for of the fulfillment of the objectives.

Project Redirection

Success lies in the ability to adapt and respond.

Sometimes changes and evolutions arise within a project and our professionals are prepared to respond at all times and adapt to possible new customer needs or the adaptation of the product for a new purpose.

What are the types of production processes?

There are four different types of production process. They are the following:

- Production on request.

- Batch production.

- Mass production.

- Continuous production.

Trends applicable to all production processes.

There is nothing new in industrial manufacturing, and nevertheless it continues to evolve and adapt to new realities. The three trends below are just one example of the business's ability to regenerate:

Sustainability: forcing adjustments and process economy to the maximum, for a better use of resources that translates into a more sustainable company, both with regard to the environment and its future.

Application of technology: as for example in the case of the combination of robots with vision systems. This issue is becoming more and more, since the use of technology applied to the field of industry makes them much more operational and, therefore, more effective.

Incorporation of big-data: Big Data allows for a better adjustment to demand and the optimization of relationships with suppliers, partners, transport companies, among others, as well as knowing more about the potential client to offer better services and products you demand.